To be a leader in coal mining and coal based products in Ethiopia. To Ensure that the operations benefit the local community and the nation at large

To be a dependable source of washed coal

Maintain the highest quality standards. Minimize the impact of operations on the environment at all stages

About ET Mineral Coal Company

ET Mineral is a leading industrial coal supplier in the nation is offering high quality washed coal ideal for cement factories, steel manufacturing plants and other similar industries requiring washed coal supply.

ET Mineral Development S.C., established with capital to more than 1 Billion Birr has completed installation of its main plant, Dawro Coal Processing site, located in the South West Ethiopia Peoples’ Region, Dawro Zone, Tarcha town, located in Dowro Zone, a region known for its rich coal resource mainly lignite and some Sub bituminous.

ET Mineral Development S.C. with a starting capital of 152 million Birr on August 28, 2013. Since its establishment, the shareholders were able to increase its capital to more than 1 Billion Birr in order to fulfill the financial requirement for the implementation of the project just finished, Dawro Coal Processing Plant. It’s share holders are Ethiopian registered companies, Ethiopian individuals.

The company is mainly established with a focused aim and set objectives, to establish a Coal Washing Plant to enrich the coal mined in the country and to supply to cement factories replacing imported coal (Import Substitution)

ET Mineral Development S.C., among the eight selected companies by the Ministry of Mines was assigned to South West Ethiopia Peoples’ Region, Dawro Zone, Tarcha town to establish a coal washing plant.

Dawro is bordered by Gojeb and Omo rivers from northwest to southwest in a clockwise direction. Dawro shares boundaries with Konta Zone to the west, Jimma Zone (Oromiya Region) in northwest, Hadiya Zone, Kembata Zone and Tambaro Special Woreda in northeast, Wolayita and Gamo zones in the east, and Gofa zone in southeast. Dawro Zone and its most neighboring zones are endowed with coal deposits mainly lignite and some Sub bituminous.

The Washing Plant Capacity:

ET Mineral Development S.C. just completed installation and commissioning of the Coal Washing Plant.

The plant is designed to process 150 tons of unwashed coal per hour or 3,600 tons per day or 1.1million tons annually. The plant can wash raw coal and produce 450,000-500,000 tons of washed coal per year, that replaces the imported coal.

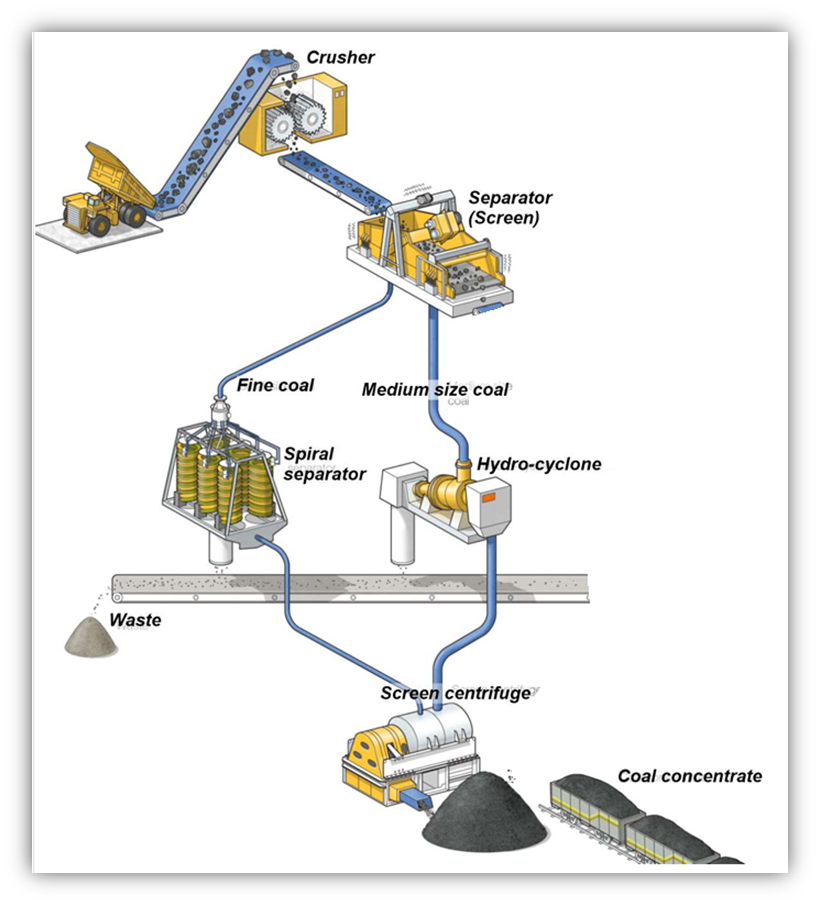

The Washing Plant Technology:

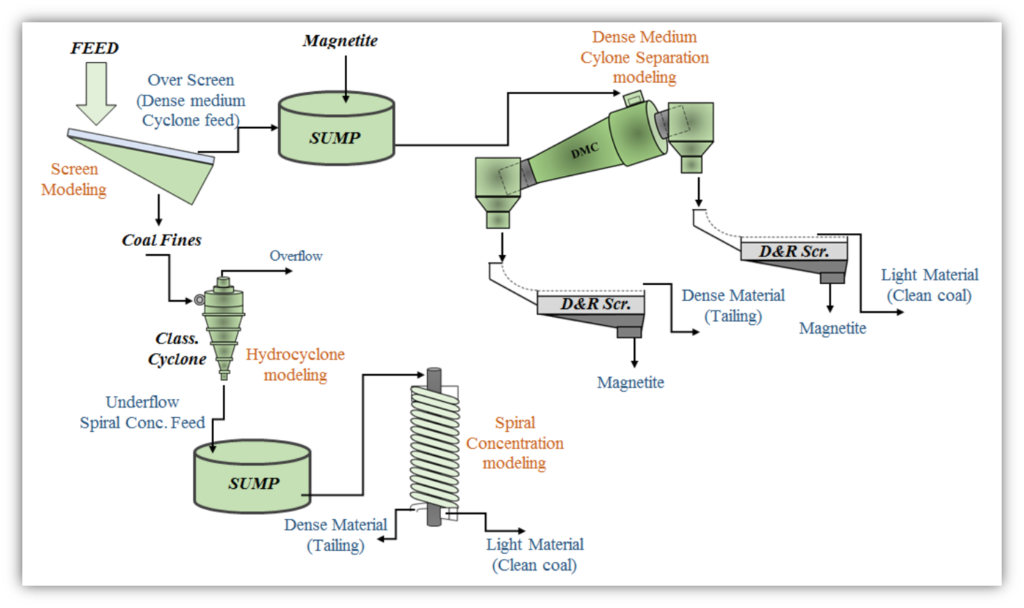

The plant uses a Heavy Media Cyclone coal washing Technology. The crushed coal is sent to a mixing box where the coal gets mixed with the magnetite medium of required specific gravity. The coal plus magnetite from the mixing box will be pumped to the Heavy Media Cyclone by a centrifugal pump. The Heavy Media Cyclones will separate washed/clean coal and rejects by density.

§Typical process flow of Dawro Coal Washing plant include:

- Crushing

- Screening into different size fractions

- Physical or mechanical processes to remove undesired impurities

- Dewatering

g

Nebil Abubeker

Founder/ Board Chair

Befekadu Assefa

Founder/ GM